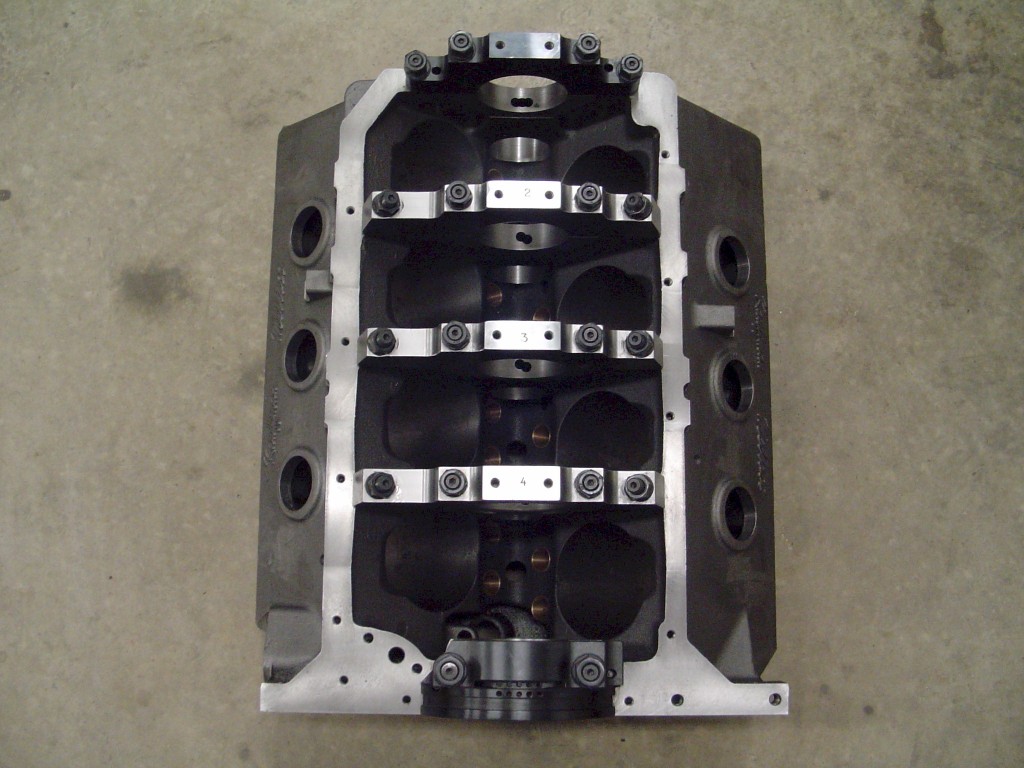

During our development of the MR-1 Pontiac block we started from ground zero. The first priority was to establish a quality standard for the gray iron material used in the casting of the block. In order to accomplish this, we contacted several foundries and met with their quality control departments to determine several things. First, the grade of gray iron used by Pontiac for stock blocks. Second, the best grade of gray iron material available to manufacture an engine block. After spectrum analysis of a Pontiac block it was determined that we could improve the the strength of the MR-1 block with the most current technology.Through this painstaking effort we were, with the help of the foundry, able to obtain this blend of precise alloys to yield a Pontiac block with the characteristics to be durable and dependable.